Aluminum PCB Manufacturing

Aluminum PCB Capabilities

1. Heat dissipation

At

present, many double-sided and multi-layer boards have high density and high

power, and it is difficult to dissipate heat. Conventional printed board

substrates such as FR4 and CEM3 are poor conductors of heat, and the layers are

insulated, so the heat cannot be dissipated. Local heating of electronic

equipment cannot be ruled out, resulting in high temperature failure of

electronic components, and aluminum substrates can solve this heat dissipation

problem.

2. Thermal expansion

Thermal

expansion and contraction are the common nature of substances, and the thermal

expansion coefficients of different substances are different. The

aluminum-based printed board can effectively solve the problem of heat

dissipation, so as to alleviate the problem of thermal expansion and

contraction of different components on the printed board, and improve the

durability and reliability of the whole machine and electronic equipment. In

particular, it solves the problem of thermal expansion and contraction of SMT

(Surface Mount Technology).

3. Dimensional stability

Aluminum-based

printed boards are obviously much more stable in size than printed boards with

insulating materials. Aluminum-based printed boards and aluminum sandwich

panels are heated from 30 °C to 140~150 °C, and the size change is 2.5~3.0%.

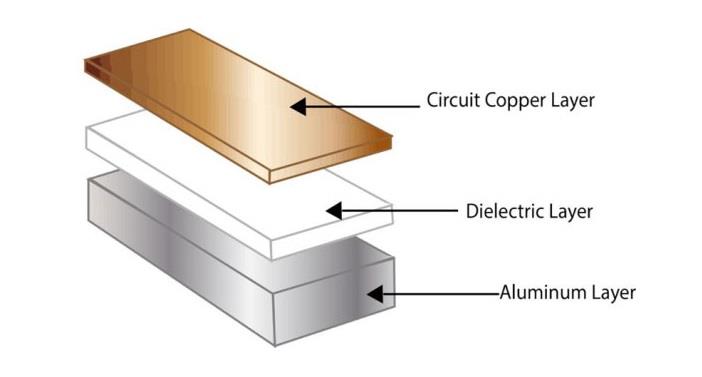

Aluminum PCB is a metal circuit board material, composed of copper foil, Dielectric Layer and Baise Layer, As shown below:

Circuit

Copper Layer: Printed circuit foil with a thickness of 1 oz to 10 oz.

Dielectric

Layer: The dielectric layer is a layer of thermally conductive insulating

material with low thermal resistance. Thickness: 0.003" to 0.006"

inch

Aluminum Layer: The base layer is usually aluminum or can also be copper. The most

commonly used thickness is 0.040" (1.0 mm), although many thicknesses are

available for selection.

Check AllWinPcba Aluminum core PCB manufacturing capabilities in the following table:

|

No. |

Item |

Process Capability |

|

1 |

Material |

Aluminum core |

|

2 |

Number of Layers |

1 Layer, 2 Layers, 4 Layers |

|

3 |

PCB Size |

1-2 Layers:1300*400mm or 650*550mm Multi-layers: 700*600mm |

|

4 |

Quality Grade |

Standard

IPC 2 |

|

5 |

Thermal

Conductivity (ω/m-k) |

1W,

2W, 3W, 8W, 12W |

|

6 |

Board

Thickness |

0.8-2.0mm |

|

7 |

Non-Plated

Through-hole size |

≥0.7mm |

|

8 |

Plated

Through-hole size |

≥0.3mm |

|

9 |

Min Tracing/Spacing |

4mil / 4mil |

|

10 |

Copper

Thickness |

1-4oz |

|

11 |

Solder

Mask |

Green,

Red, Yellow, White, Black, Blue, Purple |

|

12 |

Surface

Finish |

HASL, HASL lead free, Immersion gold(ENIG), Immersion Tin, OSP, Immersion Silver(Ag), Plating Hard Gold |

|

13 |

Finish Cooper |

1-4oz |

|

14 |

Silkscreen |

White, Black |

|

15 |

Other

Options |

Countersinks, Castellated Holes, Custom Stackup and so on. |

|

16 |

Lead Time |

3-4 days |

AllWinPcba provides one-to-one service to better suit your needs of aluminum PCB manufacturing and assembly service. We welcome your inquiry about our Aluminum PCBs: svc@allwinpcba.com

PCB Capabilities

PCBA Capabilities

SMD Stencil

Printed Circuit Boards

Product Show

Contact Us!

Our customer serviceready for your PCB

1.608.698.5398

SVC@allwinpcba.com