Metal core PCB

A brief introduction of the metal core PCBs

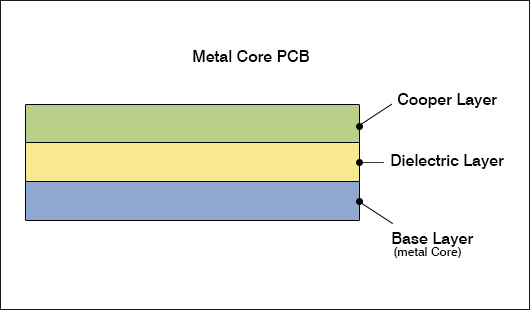

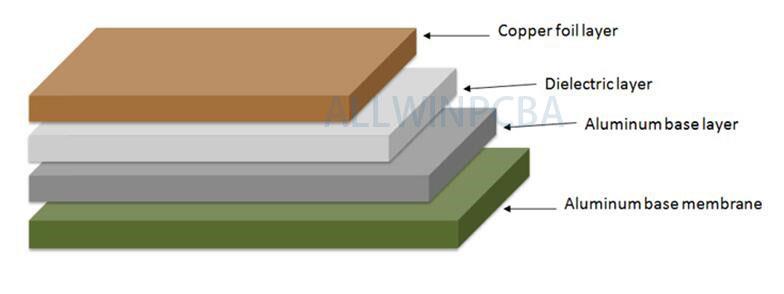

Metal core PCBs also called MCPCBs, whose substrate layer is a metal base. The most common metals of MCPCBs used are aluminum, copper, and steel alloy. Aluminum-based PCBs are the most cost-effective; they exist good heat conductivity and thermal dissipation ability at low prices. Copper-based PCBs perform better than aluminum, but the price is higher. Steel-based PCBs are harder than the first two materials, while with a lower heat conductivity. Metal PCBs are known as their excellent thermal dissipation.

Along with the improvement of electronics’ specifications, the circuits have been developed towards miniaturization, lightweight, multi-function, and high performance. Therefore, thermal issues become the vital problems to affect the stability and reliability of the electronic products. Metal core PCBs are effective solutions for thermal problems in high-density circuits when customers do the PCB assembly prototyping and mass productions.

The benefits of the metal core PCBs

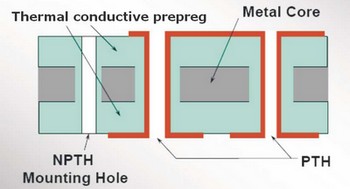

Structure of Double Sided MCPCB

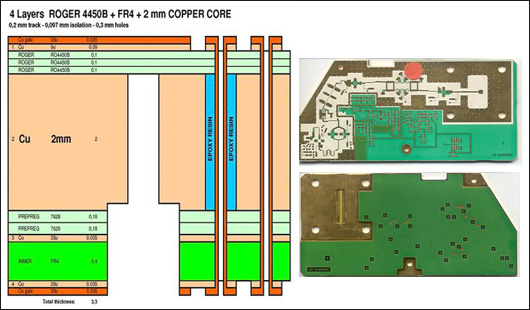

Multi Layers More Core PCB, you need to consult the salesperson first if Allwinpcba can be manufactured, The structure is similar with FR4 Multi Layers, but it much more complex to make.

1. Good dimensional stability

Aluminum PCBs and copper PCBs have high CTE (the coefficient of thermal expansion). CTE refers to describe the expansion or contraction of material on heating. High CTE means the PCBs have a good thermal expansibility, and the board size will be little changed under the high temperature when compared to the normal FR4.

2. Less distortion

Good heat dissipation of metal core PCBs makes them less prone to high temperature, which causes less distortion during signal transportation.

The advantages mentioned above make metal core PCBs ideal solutions in many applications, such as power converters, lightings, photovoltaic, backlight applications, automotive LED applications, home appliances, and so on. Aluminum-based PCB is the most common type of metal core PCBs for its cost advantage. Especially in solid-state lighting, aluminum PCBs helps achieve higher lighting levels with less quantity of LED.

The copper foil thickness of MCPCB can be 1oz to 10oz, and the metal core thickness of the boards usually is 30mil to 125mil. ALLWINPCBA offers all the types of metal core PCBs, and just contact us if you need thicker or thinner substrates. ALLWINPCBA will always keep our capabilities and equipment standards with the pace of advanced levels to provide customers with the best services of PCB prototype, PCB fabrication, component sourcing.

Choose AllWinPcba for your Metal Core PCB

AllWinPcba provides a one stop solution for all of your electronic manufacturing requirements with our experienced team and state-of-the-art assembly equipments under one roof in an inexpensive way, ranging from fast turnaround prototyping to high volume manufacturing. We have the capability to identify design and production issues during the prototype stage and solve these (in consultation with you) before mass production. Our turnkey or consigned printed circuit board assembly service is ISO ISO9001:2015-certified and RoHS compliant. We handle SMD, through-hole and mixed assembly projects. Look forward to cooperating with you, welcome your inquiry: svc@allwinpcba

Metal Core PCB Instant Online

PCB Capabilities

PCBA Capabilities

SMD Stencil

Printed Circuit Boards

Product Show

Contact Us!

Our customer serviceready for your PCB

1.608.698.5398

SVC@allwinpcba.com