What is thick copper PCB?

What is thick copper PCB?

The thick copper PCB, as the name suggests, is a thicker PCB board with a thicker line layer. Some factories will distinguish the PCB of the line layer's copper thickness ≥2oz, which is different from the general board. It is called a thick copper plate. (At present, there is no unified standard in the industry, but in the 4th edition of the "Electronic Circuit Industry Terms" released by CPCA in 2021, the definition of heavy copper PCB is: The thickness of the copper content of line conductors is greater than 105 μm (3oz) Printed boards, including single sided PCB, double sided PCB and multilayer PCB).

The circuit board is on fire, components

smoke, and even explode. It is the daily life of many electronic engineers.

Especially the power board that requires too much current, high voltage, large

current, and is very easy to fire—then how to avoid accidents?

For these types of situations, of course, choose to be designed as a heavy copper PCB.

The features of thick copper PCB:

1. The thick copper circuit board can carry a large current

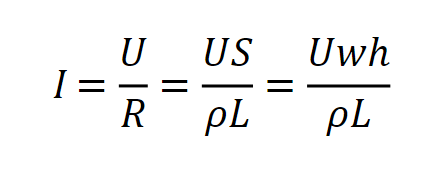

According to the formula:

(Among them, I represents load current, U

represents voltage, R represents resistance, s represents the cross -sectional

area of the line, ρ represents the resistivity, L represents the length of the

line, W represents the width of the line, and H indicates the line thickness of

the line)

In the case of line width unchanged, the loadable current I of the line is proportional to the thickness H of the line. The thicker the line, the larger the load current. Increased copper thickness is equivalent to increasing the cross -sectional area, so as to carry larger current.

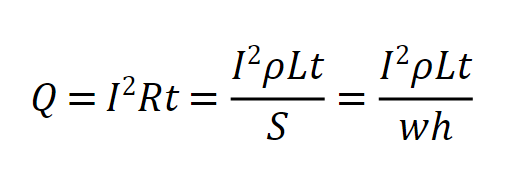

2. The thick copper circuit board can reduce thermal strain

According to the formula:

(Among them, Q represents the heat, I represents the current, R represents the resistance, T represents the time for power, ρ represents the resistivity, L represents the line length, S represents the cross -sectional area of the line, W represents the width of the line, and H represents the thickness of the line. ) At the other conditions remain unchanged, the heat of the line is inversely proportional to the thickness of the line.

Copper foil has a small conductive coefficient, which is less temperature rising through large current, so it can reduce the heat and reduce thermal strain.

Tip: The conductive coefficient is the resistivity. The metal "conductor" according to the electrical conductivity in order: silver → copper → gold → aluminum → tungsten → nickel → iron.

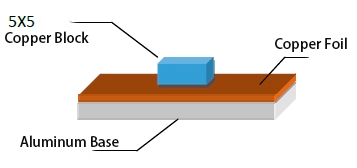

3. Heavy copper PCB has good heat dissipation

We all know metal substrates, the typical representatives of which are aluminum substrates and copper substrates, which have excellent heat dissipation performance. The heavy copper PCB, because the copper thickness is relatively thick, can also have a certain heat dissipation performance.

Copper foil has high thermal conductivity (thermal conductivity 401W/mK), which can play an important role in improving heat dissipation performance.

Tip: Thermal conductivity refers to the heat transferred through an area of 1m2 within 1H for a material with a thickness of 1m and a surface temperature difference of 1°C on both sides under stable heat transfer conditions, and the unit is W/m·K.

| Material | Conductivity K(W/m.K) |

| Diamond | 2300 |

| Silver | 429 |

| Copper | 401 |

| Gold | 317 |

| Aluminum | 237 |

| Iron | 80 |

|

Tin |

67 |

| Lead | 34.8 |

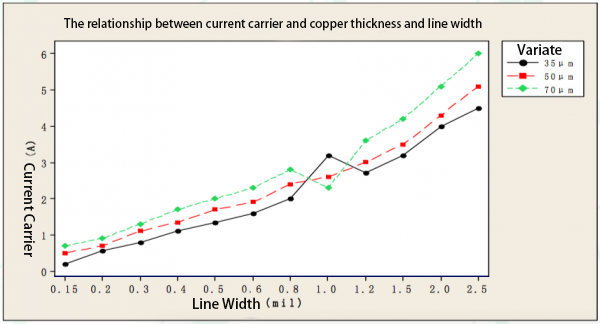

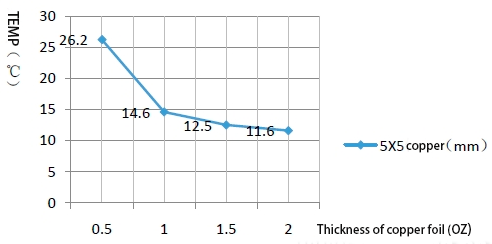

The following is a set of related experiments on the effect of copper foil thickness on heat dissipation:

According to the change curve in the above figure, as the thickness of the copper foil gradually increases, the temperature difference between the two ends of the sample gradually decreases.

Therefore, designing the board as a thick copper board can improve the heat dissipation performance of the board.

In summary, different from ordinary PCB, thick copper PCB has the significant advantages of carrying large current, good heat dissipation, and reducing thermal strain, which greatly reduces the risk of burning the board, and is an excellent option for high-current PCB design. In addition, the design of thick copper board can also increase the mechanical strength of the circuit board and reduce the volume of the end product.

Choose AllWinPcba for your Thick Copper PCB

AllWinPcba is a professional thick copper circuit board supplier, with rich manufacturing experience in the thick copper PCB field, and supports thick copper PCB proofing and mass production. Products can be widely used in mobile phones, microwave, aerospace, satellite communications, network base stations, hybrid integrated circuits, power high-power circuits and other high-tech fields. Heavy copper Multilayer PCB factory, welcome your inquiry about our thick copper PCB:svc@allwinpcba.comThick Copper PCB Instant Quote

PCB Capabilities

PCBA Capabilities

SMD Stencil

Printed Circuit Boards

Product Show

Contact Us!

Our customer serviceready for your PCB

1.608.698.5398

SVC@allwinpcba.com