New here ? Getting $50 coupon

Functional testing, also known as behavior testing, is tested according to the characteristics of the product description, user plan and operation plan to ensure that the product meets the design requirements in terms of product description and operation plan. Functional testing ensures the normal operation of the program, tests the software according to functional requirements, and tests all the features and functions of the system to ensure that it meets the requirements and specifications.

Functional testing is also known as black

box testing or data-driven testing, because it only needs to test various

functions - input data evaluation from the software product interface, test

case architecture based on written requirements, expected results and actual results

- rather than the internal structure and code of the software.

PCBA functional testing will cover hardware and software. Usually, users need to send the test plan to the manufacturer to guide the test engineer. For example, you need to list the behaviors and corresponding results (for example, when you press button one, then green light will be turned on).

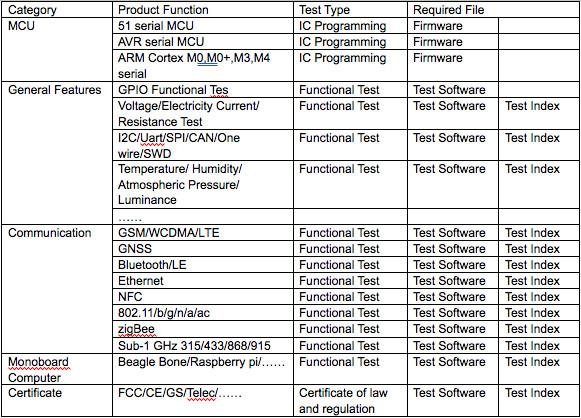

1. At present, PCBA functional tests are divided into the following categories:

1.1 Manual test fixtures

Manual test fixtures use paint and acrylic needle board to output PCB input/output and power supply, and manually simulate input/output. The results are confirmed by the testers.

Due to high labor cost and low efficiency, manual testing has been gradually replaced by manual testing fixtures. Although manual testing fixtures are only partial testing, the requirements for manual participation are lower and therefore the cost is lower.

1.2. MCU control function test

Make a fixture lock or pneumatic fixture and pull out the probe. The input/output power supply is then connected to the microcontroller circuit so that the microcontroller can run the test program and automatically measure the analog input/output.

This method has the characteristics of moderate price, high detection efficiency, guaranteed detection quality, and less human intervention. However, this method lacks versatility and is generally only applicable to machines with fixtures.

1.3. PCBA General Automatic Test System

The PCBA general automated test system is designed for most manual tests. Due to the powerful function of the test system, it can test various PCBAs and become a universal test system.

Humanized detection principle: By sampling

the model parameters, setting the error range, and comparing it with the test

board to determine whether it is qualified.

Simplicity test: manually press the needle

rod, and the system is automatically processed. Product quality can be judged

by the system to exclude the influence of artificial judgment factors.

Moreover, its speed is unmatched by manual testing.

The system consists of collection, control

board and test software. It is connected to programmable AC/DC power supply and

DC load. High-sampling products can be equipped with external oscilloscopes.

The system can test PCBA synchronization

signal, user interface, modular programming environment model and conversion.

This method is costly, but the test speed

is fast and does not require manual intervention. It is widely used in

applications and provides more comprehensive testing.

PCBA functional tests include:

·Power supply test: to check whether the

power supply is working normally or not, by testing the voltage at each point.

·Port (interface) test: to test whether

there is a short circuit or open circuit that causes dysfunction or not.

·Integrated circuit module IC/O reading and

writing function test: to check Flash & EEPROM & CPU & SDRAM &

Logic, IC, etc.

·Special function test (different circuit

board requirements): For example, infrared, an external receiver is required.

PCBA testing depends on what you are doing,

ICT or FCT. Different testing methods will vary greatly, because ICT equipment

and tooling are relatively expensive. However, ICT can give best test results,

which can bring great benefits to PCBA maintenance.

For a better understanding of PCBA

functional testing, please refer to the PCBA test function of Seeed Fusion for

reference.

PCBA test generally formulates a specific test process according to the customer's test plan. The basic PCBA test process is as follows:

Program burning→ICT test→FCT test→aging test

2.1 Program burning

After the PCBA board completes the front-end welding process, the engineer begins to program the microcontroller in the PCBA board, so that the microcontroller can achieve specific functions.

2.2 ICT test

The ICT test mainly realizes the test of the circuit open circuit, short circuit and the welding of electronic components of the PCBA through the test probe contacting the test point of the PCBA. The ICT test has high accuracy, clear instructions, and a wide range of uses.

2.3 FCT test

The FCT test can test the PCBA environment, current, voltage, pressure and other parameters. The content of the test is relatively comprehensive, which can ensure that the various parameters of the PCBA board meet the designer's design requirements.

2.4 Aging test

he aging test can ensure the stability of the product by continuously energizing the PCBA board, simulating the user's use scenario, detecting some difficult-to-find defects, and inspecting the service life of the product.

After the PCBA has undergone a series of PCBA tests, the PCBA board without problems can be labeled with qualified labels, and finally can be packaged and shipped.

AllWinPcba offers function test service with our turnkey electronics manufacturing services for PCB assembly, these services include Functional Circuit Test (FCT) and In Circuit Test (ICT) use pcba tools after PCB assembled, Visual Inspection and AOI Inspection are finished. At the same time, we can also provide FCT and ICT fixture design, production and program debugging services.

Try now! More information please check: