What is the PCB cleanliness standard for medical electronics?

29 Nov 2022 19:26:55 GMT

sandy

29 Nov 2022 19:26:55 GMT

sandy

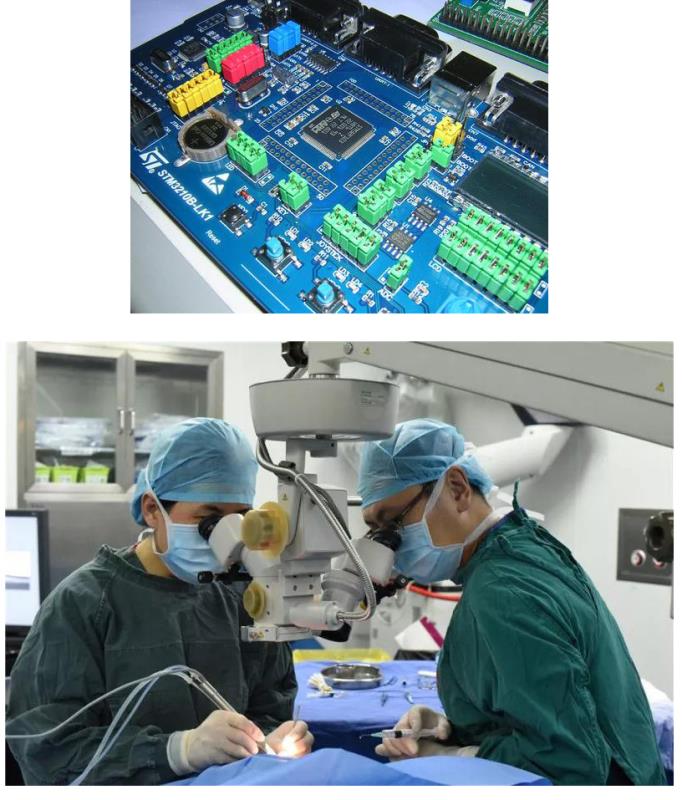

Cleanliness is not limited to the use of medical equipment. In fact, this is a major problem in the manufacturing and assembly of circuit boards used in medical electronic devices such as ion contamination. The importance of this issue is evidenced by its deep roots in all aspects of medical device manufacturing and implementation. These include some of the most extensive PCBA designs and manufacturing of medical device regulations developed by the FDA, FCC, ISO and IEC. Let's look at these, focusing on PCB cleanliness standards for medical devices and electronics.

Standards for ensuring the cleanliness of medical devices and electronic equipment

Medical device electronics are unique in that many are designed and developed to analyze not only the human body, but also when they interact directly with or connect to it. Although swabs, tongue compressors and other largely harmless devices do interact with the human body, they are classified as category 1 medical devices due to the low risk of injury to patients. Electronic medical devices are easier to classify as level 2 or 3 because of the significantly higher risk to patients.

Regardless of classification, all medical device development must comply with the quality control standard ISO13485 set forth in the Medical Device Regulations. The standard broadly covers all aspects of the design, manufacture, testing and monitoring of medical devices. This includes specific steps and measures to ensure reliable operation, which are largely dependent on cleanliness. Another standard ISO14971 covers specific stages and steps that pose a risk to the medical device development process. For example, PCB surface finish can pose a risk of introducing impurities into components.

The PCB standard that directly addresses the cleanliness of circuit board manufacturing is IPC-5704, which includes the prevention or removal of ion contamination and other types of unwanted debris. The IPC-6012D was extended to include PCBA, covering all aspects of cleanliness as well as circuit board manufacturing. For most PCBA applications, these standard rules and guidelines are sufficient. However, the requirements for electronic boards for medical devices are higher. In fact, for medical boards, the cleaning process is critical and should include testing to see if adequate levels of contaminants are removed during the process.

PCB cleanliness standards and specifications for medical device electronic products

About the cleanliness standard of PCB of medical device electronic products, there is almost a general consensus on the following two points.

1. Cleaning the circuit board after PCB assembly is crucial to ensure the normal operation of medical electronic equipment and meet the reliability of regulatory requirements.

2. Lack of specific standards to directly and comprehensively address the cleanliness of PCBA in medical devices and electronic products.

The rapid growth of the PCBA industry, particularly in the areas of board complexity and advanced functionality, presents significant challenges for regulators to update or create new rules and guidelines. As a result, a lot of attention has been focused on management and administrative requirements, rather than technical specifications, which has failed to address PCB cleanliness standards. Instead, various other criteria (e.g. biological assessment of medical devices ISO10993 - Part 1: Assessment and testing in the risk management process for biocompatibility and related developmental risks, as well as IEC60601, which provides a set of test protocols to assess patient safety when using specific medical device electronics, as well as many recommended cleaning methods, are listed below.

Method for cleaning the electronic PCBA of medical devices

1. Ultrasonic cleaning machine

By far the most recommended method for cleaning PCBA is ultrasonic cleaning. The method utilizes a temperature-controlled process at a set time interval. The effectiveness of this method depends on the type of solution used.

2. Automatic cleaning machine

Automatic cleaners are usually water-based processes where boards are loaded into baskets, dipped in solution, and then dried. Although effective, care must be taken as some solutions may be harmful to some materials.

3. Clean it manually

Good quality old elbow grease can also be used. This method is not effective for small boards with hard-to-reach areas. However, some components (such as microphones) must be manually cleaned.

As shown above, determining the best cleaning method is one of the most important steps in a good cleaning regimen.

PCB cleaning solution steps

Whether determined by you or by your CM (as is often the case), following these steps will yield the best results.

1. Identify possible soil or contaminants

2. Identify surface compatibility issues

3. Select a cleaning method

4. Determine the temperature parameters

5. Determine the cleaning cycle

6. Determine the flush solution

7. Determine appropriate verification methods

AllwinPCBA has our own PCB circuit board and SMT assembly factory in Shenzhen, China, and we also have service offices located both in China and in Texas, USA (welcome to visit). If you have any needs for your PCB and PCBA, Please feel free to contact us: svc@allwinpcba.com