The role of chip mount to PCB

27 Jul 2022 19:19:52 GMT

administration

27 Jul 2022 19:19:52 GMT

administration

These are not the old, traditional PCBS we grew up with; Instead, they are a new type of circuit board, mainly small rigid and flexible circuits, or a combination of both, called rigid-flexible combination. An increasing number of small electronic products, such as wearables, portable devices, and iot devices, are based on these updated miniature circuit boards.

In 2019 and beyond, microelectronics will play a crucial role as today's advanced electronics are shrinking the PCB space. One reason boards have shrunk in size is that components have shrunk in size and become more delicate, and it has become more difficult to assemble, inspect, and test products.

For example, many of these smaller PCBS cannot pass through traditional PCB assembly and manufacturing lines. Increasingly, such boards must undergo specialized microelectronic packaging, including lead bonding and chip connections.

Chip connection is a relatively new area of small PCB manufacturing. In short, it is the process of connecting a chip or tube core to its package, substrate, or rigid, flexible, or rigid-flexible circuits. In fact, it may even involve connecting one chip to another.

Fine processing

The chip mount method to be used depends on the thermal conductivity and heat dissipation. Therefore, before the chip connection process, each chip is carefully checked and analyzed for thermal conductivity to determine the amount of heat it will give off.

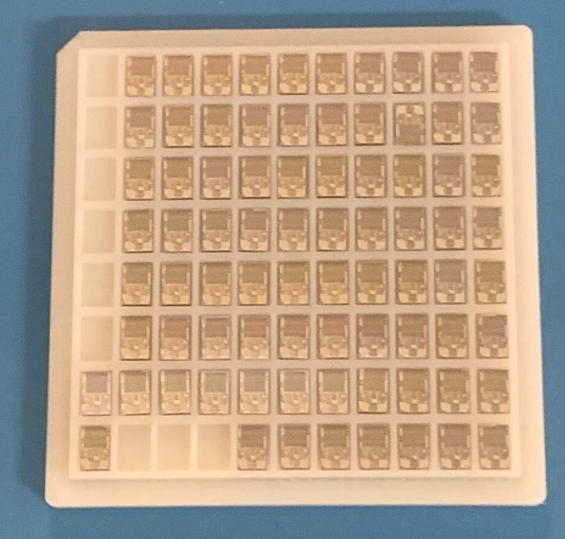

Chips are usually found on tape, wafers or in waffle trays. The Waffle tray or chipset has many chips already cut (Fig. 1).  Fig. 1, Waffle Pack with chip

Fig. 1, Waffle Pack with chip

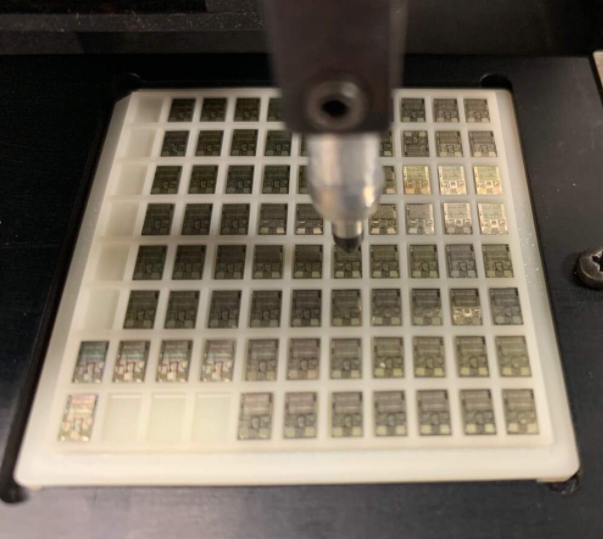

The chip connection process begins when the target chip is picked up from a Waffle tray or wafer pack via a small vacuum suction tool (FIG. 2).  Fig. 2, Vacuum suction tool for picking up chips

Fig. 2, Vacuum suction tool for picking up chips

After vacuum release of the core, it is precisely aligned with the substrate or PCB and then permanently attached using one of three methods. The epoxy and solder used for the patch may be nonconductive or conductive. When conducting chip mount, there should be perfect contact between chip/chip and substrate /PCB; In addition, there should be no gaps.

In addition, the adhesive that attaches the chip to the substrate must be very precise. This process is very sensitive; In addition to picking up the chip, it must also be placed on the substrate without damaging or destroying it. The chip bonding created should be able to withstand extremely high temperature ranges without any loss of productivity, any loss of performance, and any significant degradation.

Epoxy chip connection

Typical chip bonding methods are epoxy bonding, eutectic and solder bonding. Epoxy bonding processes may involve silver epoxy glass or polyimide based materials. This epoxy is dispensed using a very fine dispenser that dispenses quantities very precisely with tolerances in microns. In this case, the substrate needs to be heated to temperatures ranging from room temperature to 200°C, depending on the type of epoxy used. This temperature allows the epoxy to cure correctly, allowing it to adhere to the substrate and thus precisely form a junction between the substrate and the chip.

When the epoxy is dispensed, it covers the area where the chip connection is needed and creates a rounded corner at the edge of the bond. If too much epoxy is distributed, contamination and misalignment can occur. Coplanarity will also become an issue, in which case the chip will not function properly. In contrast, if not enough epoxy is dispensed, cracking, voids will occur, and subsequent joints will be suboptimal.

As shown in Figure 3, the requirements for the extremely precise assignment to be performed. In addition, highly sophisticated detection tools are required to achieve perfect chip mount. The adhesives used are usually not conductors - they are electrical insulators and do not conduct heat well. To make them more thermal conductive, silver or gold materials are used, thus reducing the thermal resistance to a lower value.

Compounds that add gold, silver, silicon carbide, beryllium oxide, or different elements help solidify these binders at lower temperatures. Epoxy bonding can also be used to connect chip sizes of many different materials.

Eutectic chip connection

This technique uses a eutectic alloy to attach the chip to a cavity or substrate. The substrate in this application can be ceramic or metal such as aluminum or copper, which are commonly used in high-power applications such as microwave and radio frequency components. The reason for using a eutectic patch process (as opposed to using a bonded patch process) is that the eutectic method can handle temperature ranges of 300°C or higher. Higher temperatures are required because substrates such as ceramics and metals have higher melting points.

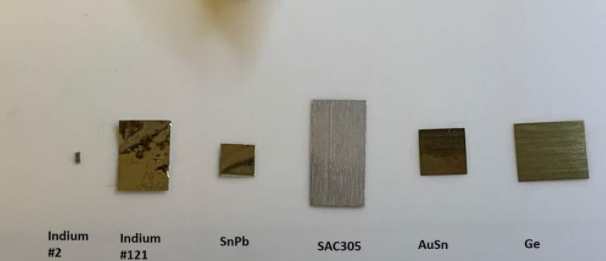

Eutectic chip bonding -- also known as the "flux-free bonding process" -- a thin metal layer called a prefab (FIG. 4). The preform is an alloy (mixture) of two or more different elements (gold-silver or gold-tin or similar) that can be used to create joints under an inert atmosphere. Since they are permissive, these preforms melt at a lower temperature than the substrate.  Fig. 4, Also known as "flux-free welding," eutectic chips are connected using thin metal layers called preforms

Fig. 4, Also known as "flux-free welding," eutectic chips are connected using thin metal layers called preforms

For example, pure gold has a very high melting temperature of more than 1,000°C, while silicon has a melting temperature of more than 1,400°C. On the other hand, preforms made using tin and silver allow melting at 231°C, gold tin at 295°C, gold and Germanium at 350°C, and gold and silicon at 400°C, making it much easier to create robust joints in a controlled temperature range.

Other reasons for using gold-based preforms are that the element has high electrical conductivities - both electrical and thermal - thus providing an excellent way to dissipate heat.

Welded chip connection

Welded connections are similar to Surface Mount Technology (SMT) joint creation. Solder bonding is a common type of chip bonding due to the high thermal conductivity of the solder material itself.

As we have seen, when we also consider the various methods discussed above, the chip mount process may experience extreme temperature variations. For example, for tin-lead SAC 305 or some similar solder, the temperature range of the soft solder joint process is 180°C to 250°C. For solders made of gold-tin, gold-silicon, or similar alloys, high temperature solder joining methods may exceed 250°C or more. Welded connections are also important when it comes to heat dissipation in devices such as leds.

An important aspect of solder attachment is that the chip requires flux. Prior to this, the initial solder alloy needs to be pre-plated on the chip metallization and the substrate metallization. If a certain layer is required, a slightly different chip and substrate composition is required. Once executed, the chip is placed on the substrate using a chip placer.

When using the solder connection method, a wire is fed into the system, where it warms up, then melts the solder and forms a joint (after which the flux must be removed from the chip before encapsulation).

The excellent characteristics of solder attachment technology include its robustness, mechanical strength, good heat dissipation and high thermal conductivity.

Wire bonding

Once the core connection process is complete (using any of the above techniques), lead bonding is performed using an additional process that connects the pads on the core/chip to the corresponding pads on the substrate /PCB. These lead bonding can be achieved using gold, aluminum, copper, or (in some cases) silver wire.

In short, chip mount is becoming a more prominent technology for small PCBS such as rigid, flexible, and rigid-flexible combined circuits. Therefore, it is important for OEM designers to have a good grasp of the three types of chip mount methods to select the most suitable method for their applications.